"Essential Fastener Insights: FAQs and Best Practices"

Release Time:

Aug 15,2025

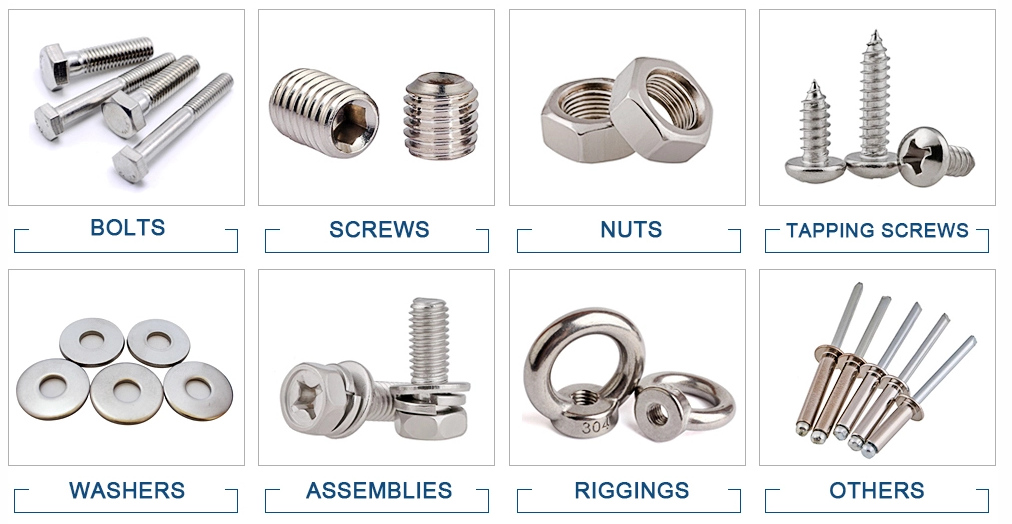

Q: Can't tell bolts from screws?

A simple rule: Components used with nuts are typically bolts. Those driven directly into a material (pre-tapped holes or self-forming threads) are usually screws. Note: Some ambiguity exists (e.g., hex head machine screws).

Q: Are washers optional?

Absolutely not!

Flat washers protect surfaces and distribute clamping pressure.

Spring washers maintain tension against loosening.

Neglecting washers risks: Connection failure, surface crushing, or fastener fracture.

Q: Is tighter always better?

A dangerous misconception!

Over-tightening (excessive preload) causes:

Bolt stretching/rupture (plastic deformation)

Crushed components (e.g., aluminum alloys, plastics)

Stripped threads

Insufficient preload causes: Connection loosening and failure.

Critical applications (e.g., wheel hubs, engine blocks) require calibrated torque wrenches.

Q: Why do threads strip after few uses?

Potential causes:

Poor thread quality

Overly soft material

Cross-threading (misaligned insertion)

Thread wear from repeated use

Thread damage from excessive force

Q: How to handle rust?

Light rust: Treat with rust remover/wire brush.

Severe corrosion or critical joints: Replace immediately.

Prevention is key: Select corrosion-resistant materials/surface treatments for the operating environment.

Keywords:

More information